Machine Shop

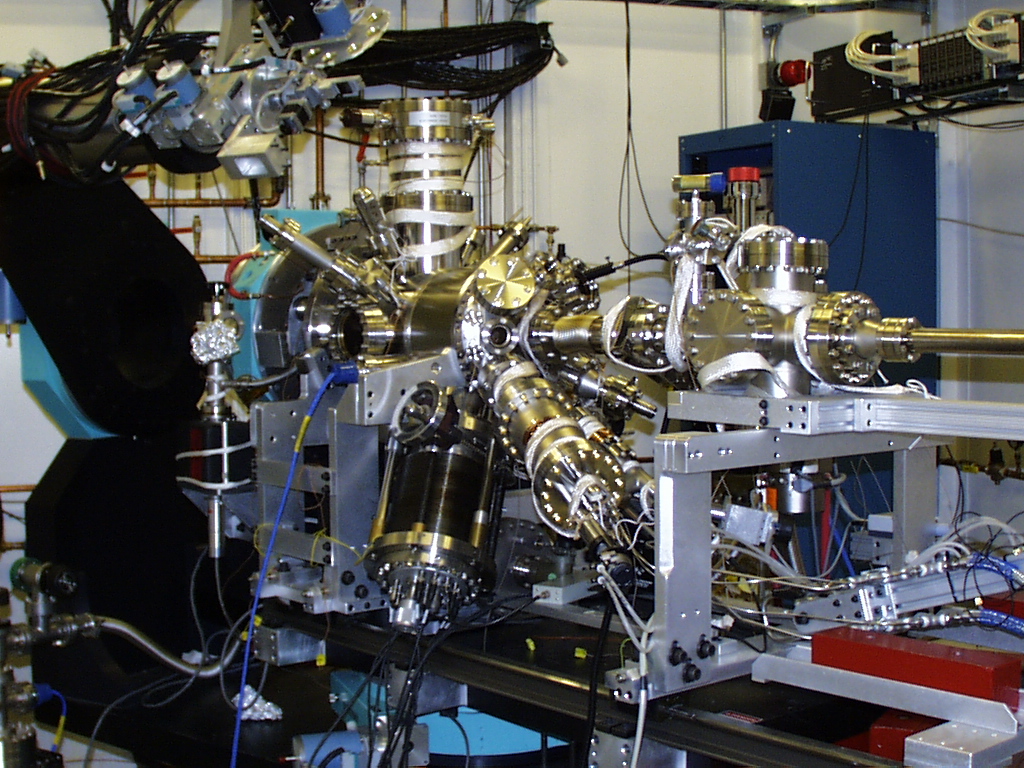

Ultra-High Vacuum Surface Science Chamber

Since 1966, the mission of the Physics Machine Shop has been to aid in research efforts throughout the University System, as well as Research Facilities across the United States and abroad. The primary focus is to create science instruments with a high degree of precision, from design, to fabrication, to assembly. This is accomplished with the use of both manually operated machines and computerized CNC machines.

The image at right shows an instrument that was developed by Prof. Paul Miceli (MU) and Prof. Edward Conrad (Georgia Tech) in collaboration with the Physics Machine Shop. Using intense synchrotron radiation at the Advanced Photon Source at Argonne National Laboratory, the instrument is used to investigate the structure and non-equilibrium behavior of interfaces, in real-time, during the growth of nanoscale materials.

| Hours: Monday–Friday, 8 a.m. – 5 p.m. | Shop rates for: Internal customers - $80/hour External customers - $110/hour |

| Address: Rm. 35 Physics Bldg. University of Missouri Columbia, MO 65211 | Contact: callaisc@missouri.edu Tel. 573-882-4541 Fax. 573-882-4195 |

Double-bent silicon wafer monochromators

Purpose-built sample cells

Cryogenic applications

X-ray scattering

Neutron scattering

High pressure cells, to 0.6 megabar Pill pressure

High temperature cell for furnace application

Sample manipulator devices, 1–5 axes

Shielding

- Neutron

- X-ray

- Thermal

Instrument Enclosures

Single crystal silicon neutron interferometers

Collimators

- Neutron solar collimators

- Neutron oscillating radial collimators

Stretch film collimators

High vacuum systems, 10-6 range

- Liquid helium cryostats

- Liquid nitrogen cryostats

- High temperature furnace

UHV systems (10-10 range)

Stress/strain systems

Atomic force microscope

- Research Instrument Design

- Computer Aided Design

- Inspecting and measuring to 0.0001” (0.00254 mm)

- Precision Lathe and Mill

- Precision Surface Grinder

- Welding Ultra-High Vacuum Components

- Helium leak checking to 10-9 cc/s leak rate

- Lab equipment repair and preventive maintenance

Physics and Astronomy, Chemistry, Electrical and Computer Engineering, Christopher Bond Life Sciences Center, University Hospitals and Clinics, MURR, (all from UMC), N.I.S.T, Washington, DC, Oak Ridge National Laboratory, Brookhaven National Laboratory, Argonne National Laboratory, Institut Laue-Langevin, Grenoble, FR, Others in Peru, Chile, Germany, Sweden, South Africa

Steels, Stainless Steels, Aluminum, Alumina, Brass, Copper, Tungsten, Tantalum, Molybdenum, Plastics, Phenolics, Silicon